For a change I don’t have to make a secret of the exact location of a Lost Place. The abandoned power plant in Fier cannot be overlooked or missed. You basically just have to follow your nose, because one thing is certain: If you didn’t smeel the crude oil, you haven’t been to Fier.

Dieser Artikel ist auch auf Deutsch verfügbar. Click here to find out more about Albania!

For an overview on Albania, have a look at the introductory post.

The Old Greeks already knew of the petroleum deposits near Fier even before the birth of Christ. Asphalt chunks were dug out of the ground and burned in the local hearths. Since the 1930s crude oil has been extracted industrially. If you want to see the typical oil pumps with their “nodding” beams, you don’t have to go to Texas – in Fier you can see them on both sides of the main roads.

Fier became one of the most important cities in Albania during the era of industrialization after the Second World War. Industrial plants and a refinery were constructed. In the 1960s, Korporata Elektroenergjitike Shqiptare (Albanian Electric Power Company, KESH) constructed a huge steam power plant (Termocentrali i Fierit) with an adjoining fertilizer factory.

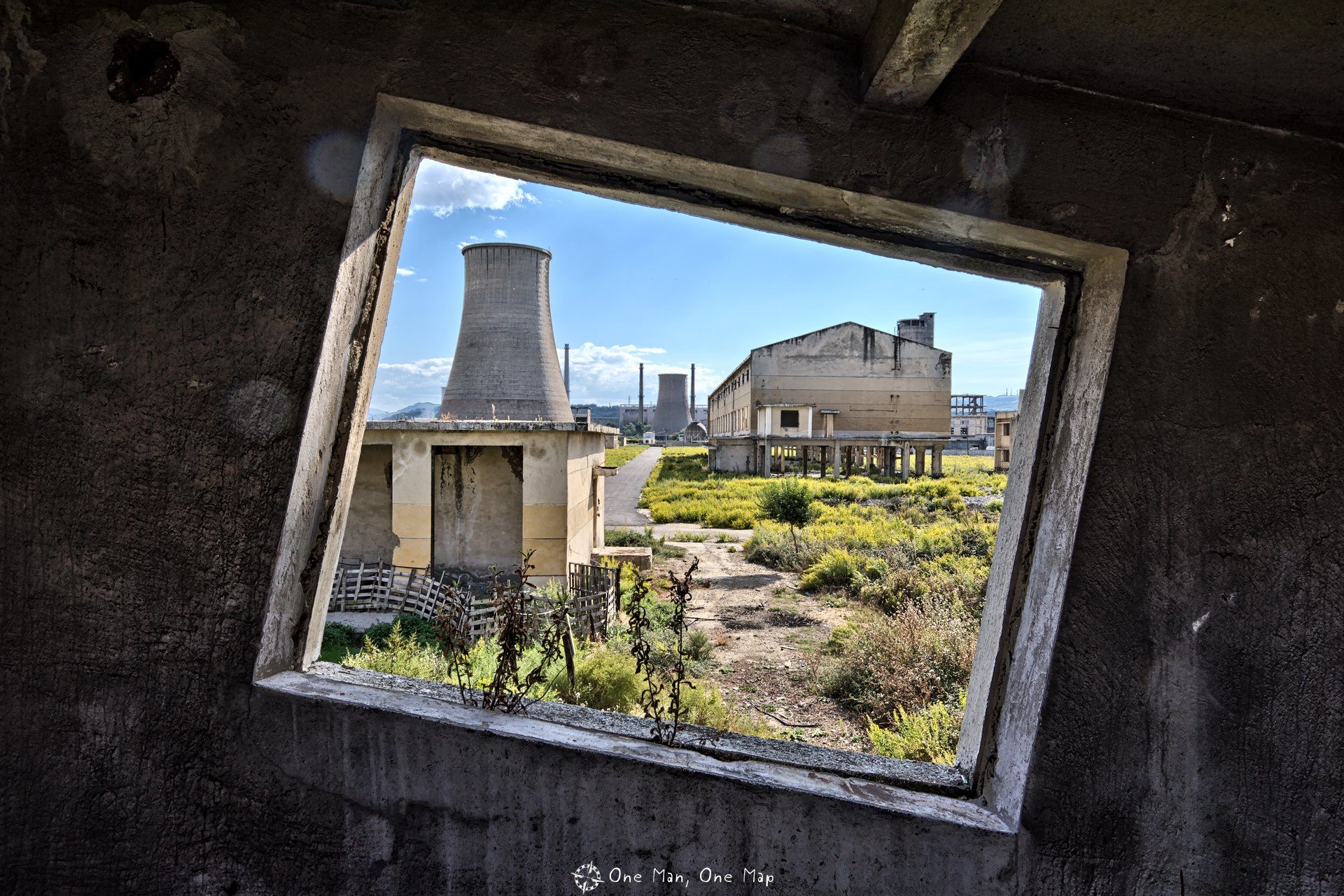

The oil-fired steam power plant with an output of 186 megawatts was the largest combined heat and power plant in all of Albania. The heavy oil for the combustion chambers came from the neighboring refinery. At the beginning of the new millennium the power plant was hardly operating anymore, often producing just 20 megawatts instead of 186. In 2007 it was finally shut down and the entire area sold to a Greek investment group for the symbolic price of a single Euro.

Electric power generation from renewable sources was to start in 2009. But then the Financial Crisis hit Europe and everything was put on hold. Since then the facilities continue to decay. A few years ago there was probably more to see, in the meantime most of the metal remains were sold off and some of the buildings have been demolished.

There were still some things going on at the southern end of the 1.5 square kilometer facility. The 220 kilovolt electric power distribution station was still in operation. The old refinery on the other side of the road was still running, fuel trucks kept passing all the time. Some smaller companies had set up shop in some of the smaller buildings. Workers were smoking in the sun in front of a small canteen.

Nobody tried to stop us as we walked in the direction of the huge cooling towers. Well, why should they. In Albania people rarely care about things they are not directly responsible for – and apparently none of the people present felt responsible for these concrete ruins.

The Power Plant

Seven large cooling towers were still present on the site. Three were located next to the old power plant, four more spread out over the rest of the area.

Unfortunately the actual power plant on the southern side was unreachable. We had already come pretty close, but a fence blocked the way, and from the other side we could hear very loud barking. The dogs probably belonged to the guards who watched the high-voltage power distribution station still in operation.

In this building there are (or were?) the remains of the six boilers. Five smaller ones with 12 to 25 megawatts of output power came from China, a large one with 60 megawatts from the Czech Republic.

We continued North, past endless ruins of buildings of unknown function.

Some of the smaller buildings seemed to have been inhabited by the homeless. We didn’t run into anyone, but found some clues.

The Fertilizer Factory

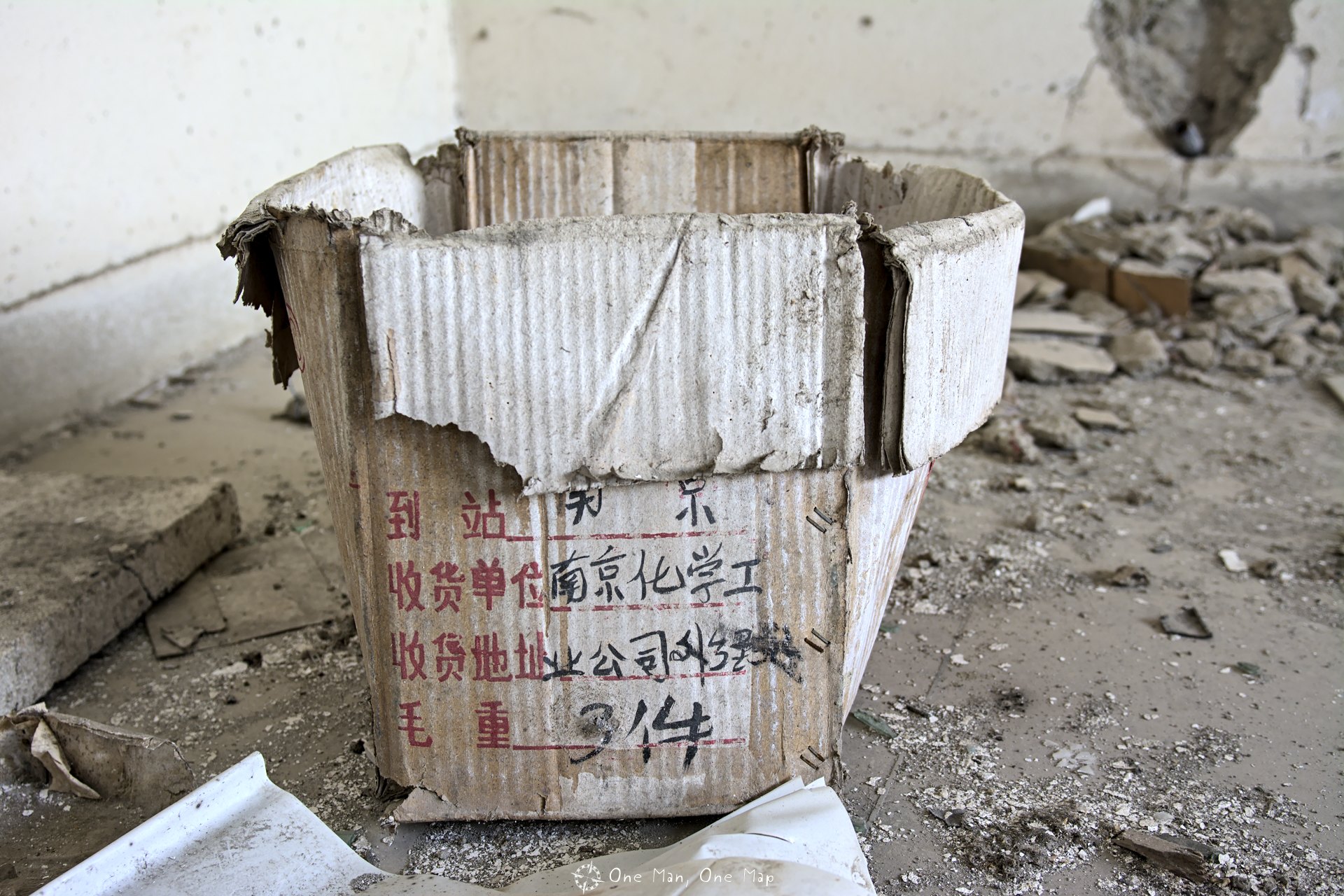

The fertilizer factory was located on the Northern side of the site. Production began with the construction of a single production line for ammonium nitrate bought from Italy in 1966. In 1976 a second line was added, in 1990 a third, both from China and designed to make urea fertilizer. Albania didn’t pay for the expensive equipment with hard foreign currency, but with raw materials. China for example accepted to be paid in bitumen.

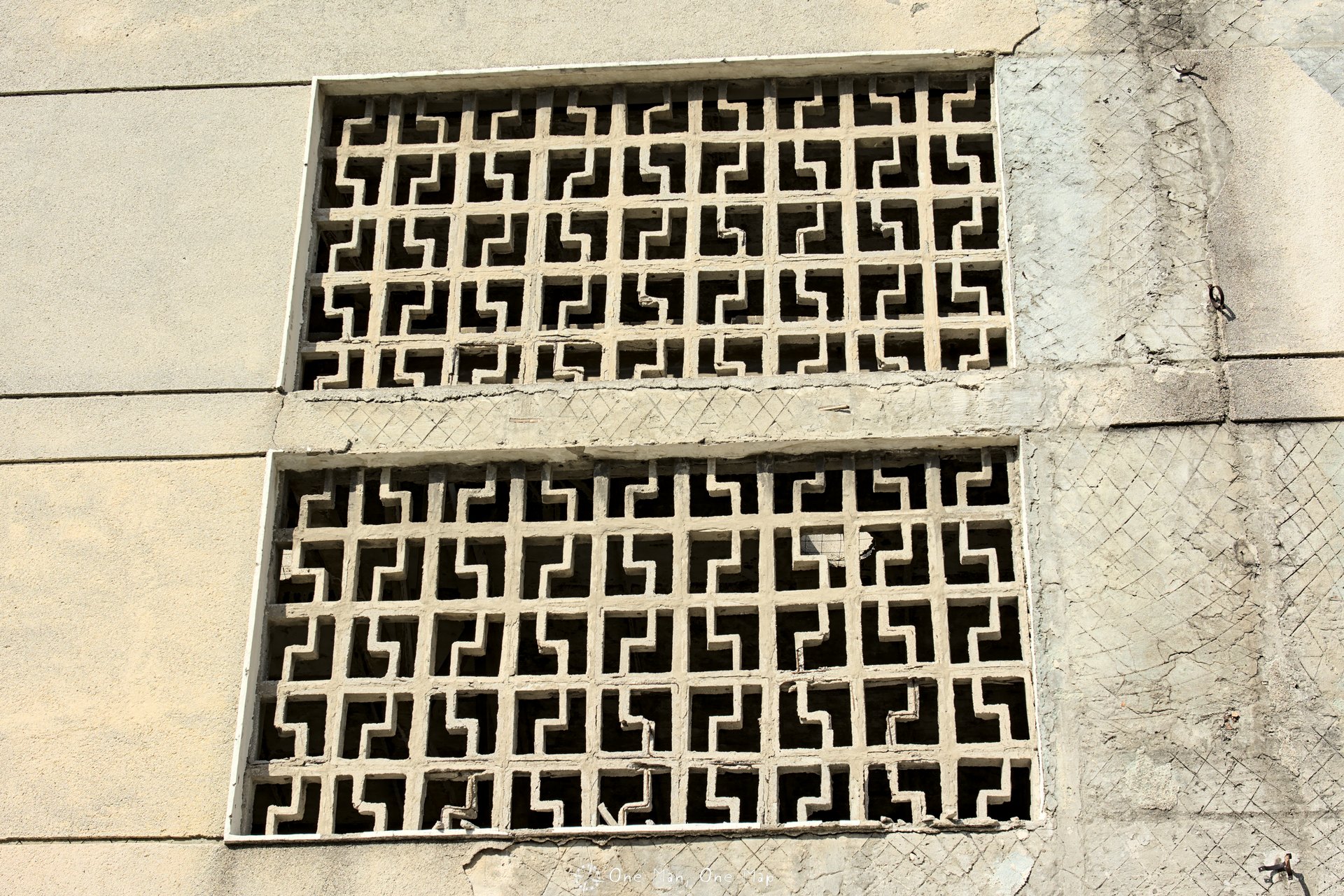

The factory had its own driveway with a guardhouse and a gate. Probably the trucks got on site here and were then loaded up at the buildings with the “wing-shaped” roofs. The most striking building was of course the big absorption tower.

It was no coincidence that the factory had been constructed in this exact spot. The two most important things for making artificial fertilizer are natural gas and process heat in the form of hot steam. The first one came from the oil refinery a couple hundred meters away, the second one from the steam power plant.

The shape and location of the buildings are an indicator for what they were probably built for. Ammonium nitrate for example is made from two basic ingredients, nitric acid and ammonia. Nitric acid can be made from natural gas by first making nitric oxide in an intermediate step, then mixing it with water in a scrub tower and circulating it until the concentration is high enough. Usually these sprayer towers have four to five levels. The concrete structure next to the tower happens to have five levels. So that could be a match.

The highly concentrated nitric acid is then discharged and reacts with ammonia in an absorption tower to form an ammonium nitrate solution. I think this absorption tower was hard to overlook. And the last step, the evaporation, crystallization and packaging of the final fertilizer pellets in a large hall, also seemed to have happened here.

The tower already looked very impressive from the outside, but even more so from the inside. A dilapidated staircase led to the very top. In older reports from a few years ago visitors seemed to have even climbed to the top. I can’t recommend that!

At the bottom of the tower there was an opening into a long tunnel with a staircase. Presumably the ammonium nitrate solution was transported to one of the processing halls through a pipeline inside of the tunnel. From the outside we could see that the tunnel actually led to one of these halls.

The production lines were probably housed in the long halls. However, only two of them were left. There should have been three.

The liquid ammonium nitrate solution was heated to 300 degrees Celsius inside of heating pans in the production halls, stirred and slowly crystallized. This process formed the typical artificial fertilizer granules which are still commonly used in agriculture. A protective coating was probably applied in the last step.

At peak times up to 1,000 tonnes of fertilizer ran off the assembly lines per day. In 1993 more than 900 people still worked in the fertilizer factory. But there was an increasing lack of the main raw material, natural gas, and spare parts. From the 1990s on, Albania was increasingly dependent on artificial fertilizers imported from abroad.

I wonder what was going on in these round buildings? Maybe the freshly made artificial fertilizer was stored here?

Perhaps some kind of crane could have been located on the concrete base in the middle, with the artificial fertilizer granules around of it in a big pile. Similar constructions can also often be seen in gravel pits. But that’s not more than an educated guess.

The Laboratory

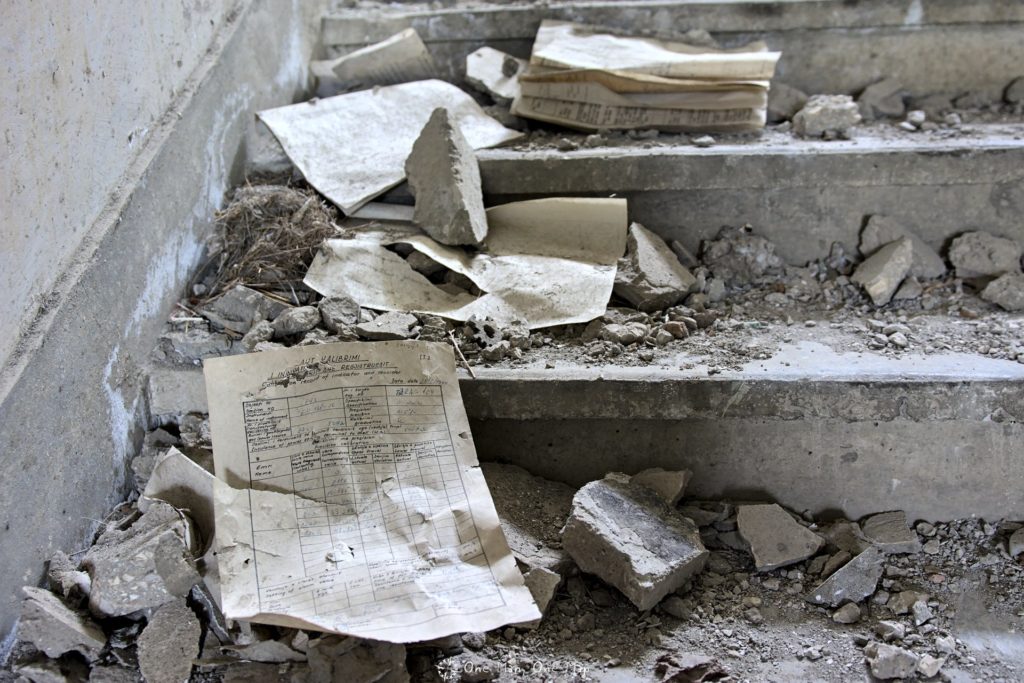

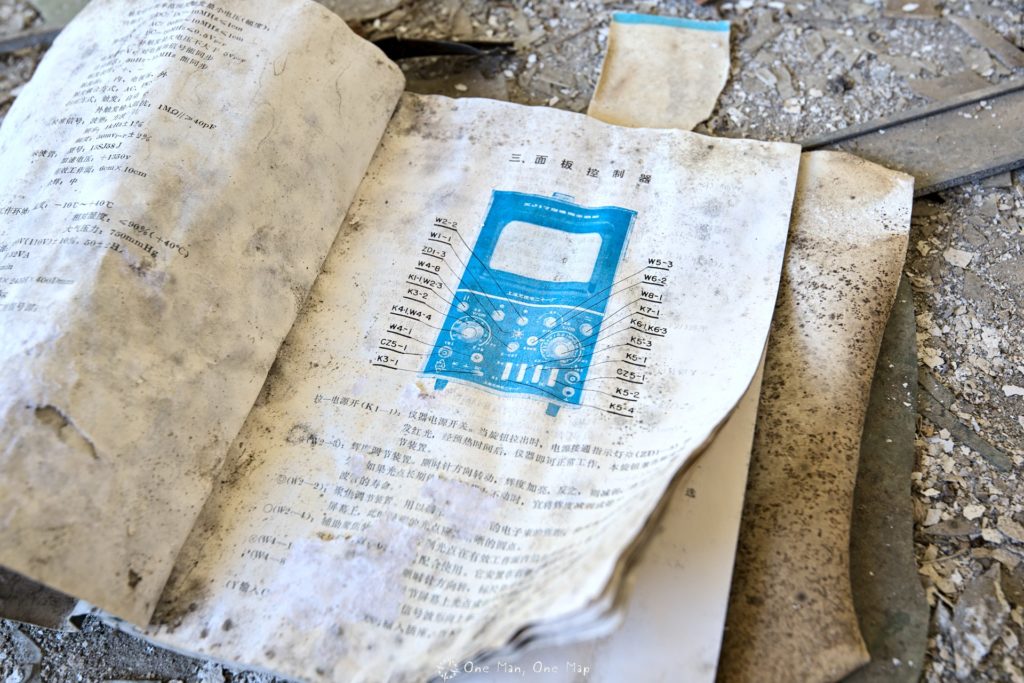

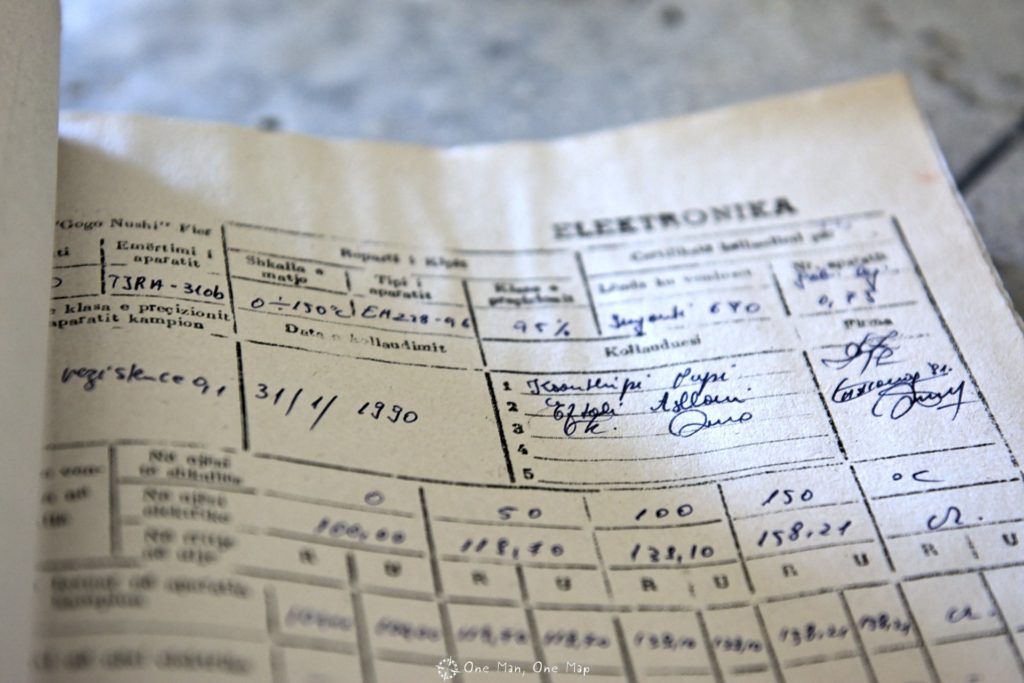

A large building to the northwest had housed laboratories and administrative offices. Here the demolition work had not progressed as far as elsewhere, and there were still many treasures to discover

The furniture had been taken out a long time ago, but there were heaps of old documents scattered around the floor. Obviously someone had plundered the archive in search of something valuable.

In addition to manuals for electronic measuring devices, lots of lab records were among the documents. The dates on the papers ranged back to the year 1990, so around the time when the third production line had just been built.

I can understand the presence of gas masks in the lab. But what was it with all the shoes?

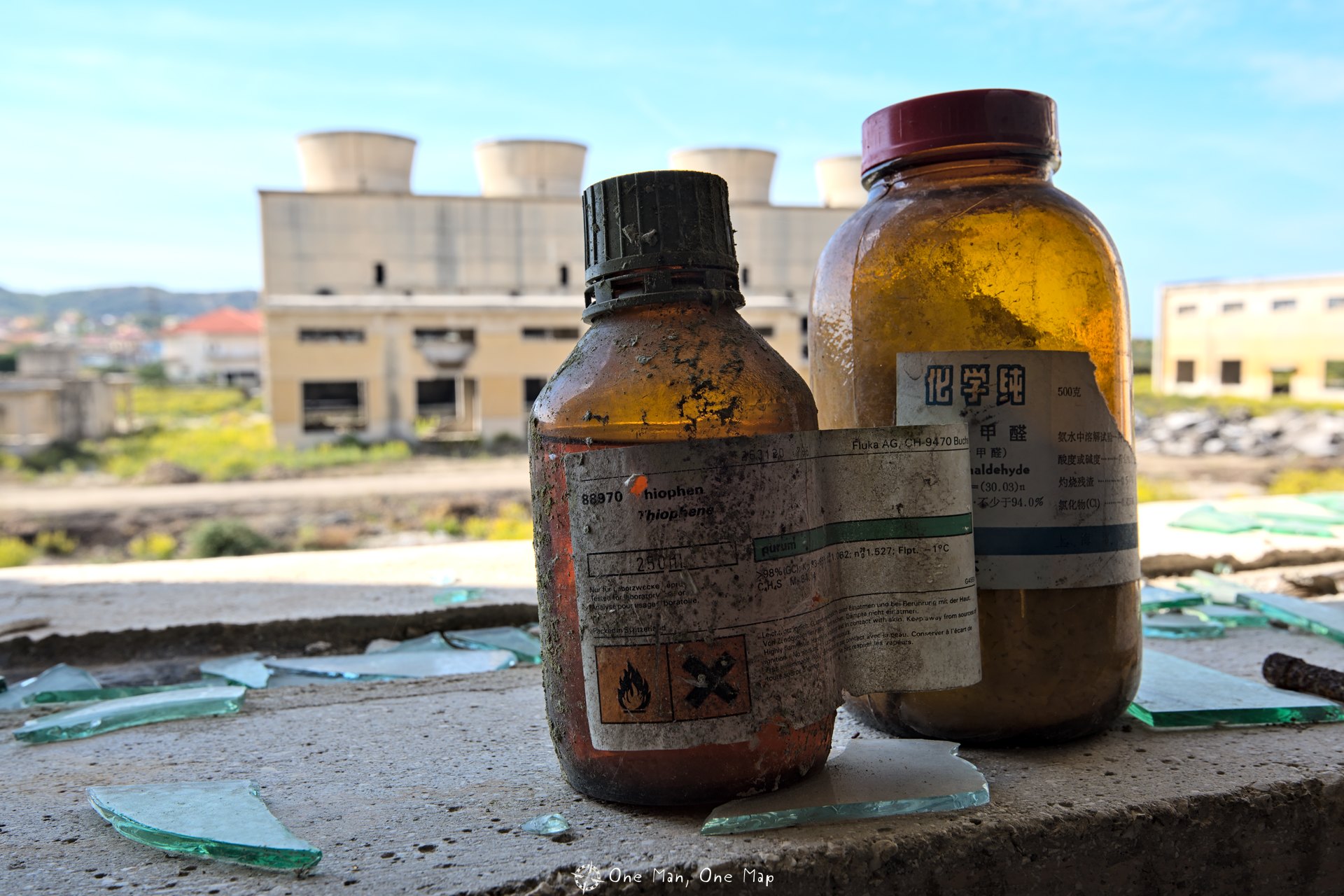

Two glass bottles with Thiophene and Formaldehyde were standing on the windowsill of the lab room. The former is flammable, the latter poisonous and corrosive. Black spots on the floor indicated that some things had already been spilled and reacted with each other. One of the many reasons why you should always be careful and not touch anything in a Lost Place like this one…

Next to the laboratory and administration building was the last intact structure, the giant cooling unit. The production of artificial fertilizer releases a great amount of heat. The towers, reactors and production lines have to be constantly cooled. Judging from the size of the coolers, I estimate that the cooling capacity must have been of several megawatts.

The power plant and the fertilizer factory may no longer be in production, but the city of Fier will continue to be associated with oil and gas. Since 2015 the Trans-Adriatic Pipeline is under construction and will connect Turkey to Southern Italy via Greece and Albania. After completion in 2020, Europe can then be supplied with natural gas all the way from Azerbaijan. Fier plays a central role in this pipeline project. A large gas storage facility in the city should serve as a buffer in case of supply bottlenecks and interruptions.

In the next post we will continue to the most beautiful part of Albania: the South. There we will find mountains, the Adriatic Sea, beaches, sunsets, abandoned mountain villages and much more…

This post was written by Simon for One Man, One Map. The original can be found here. All rights reserved.

Hi. I hope you don’t mind my asking some questions about the power plant complex @ Fier. I am going to Albania and would love to visit this place. When you visited this place, was there no guards at all? No gate? Could you just walk around freely? Do you remember if one could park one’s car somewhere nearby?

Thank you.

Sincerely,

Sylvia